Lab Plastics & Rubber Mixing Mill

Model

AT-R7024 series

Applications

Used to plasticize and mix various rubber, resins, silicones and additives in small batches for prototyping and sheet forming.

Standards

ISO 2393, ASTM D3182, etc.

Lab Plastics & Rubber Mixing Mill Description

Lab Plastics & Rubber Mixing Mill is known as the Lab two roll open mill, and it has two horizontally arranged and rotating rolls to process and mix various polymers in small batches by means of intense kneading and shearing action.

In the rubber industry, you can use the rubber mixing mill to masticate raw rubber and synthetic rubbers including NBR, SBR, BR, etc. to achieve the required plasticity. In addition, it can also be used to repeatedly disperse and incorporate raw rubber with various additives including accelerators, fillers, vulcanizing agents, etc., to finally obtain a uniform rubber compound for further molding and processing in the laboratory. In the plastics industry, you can used the mill to plasticize and mix resins and other additives in small batches to obtain sheet materials of specified thicknesses with even dispersion and good interpenetration between components for laboratory recipe development, color comparison, trial production, molding, aging test, etc.

AmadeTech laboratory plastics and rubber mixing mills are made with a compact size and sleek look. The mainframe is constructed with welded rectangular steel tubes to make it fully self supporting. Flexible configurations allow you to add or subtract various optional features to suit your needs.

Rugged Rolls

One piece of two roll mixing mill contains two rolls of the same size that can rotate inwards in opposite directions. As the roll rotates, the polymer material is drawn into the gap between the two rolls and subjected to shearing and squeezing to carry out the mixing. We supplied a scrapping knife for you to cut, fold, turn over the batch material over the front roll throughout the operation.

Our rolls are machined from a solid rod of highly rigid metal. Depending on the application, AmadeTech is capable of providing rolls made of a variety of materials including chilled cast iron, KDB high carbon steel and alloy steel (please refer to the FAQs below for the differences between them). These rolls have been hard chromed and further processed to allow for outstanding mechanical strength and hardness as high as 60 HRC, excellent heat conductivity and corrosion resistance. In addition, we can have your rolls with different surface treatment processes, including chrome-plated rolls, mirror rolls, matte rolls, etc., to cater to different polymers.

mirror rolls

chrome-plated rolls

matte rolls

Roll Heating & Cooling Available by Electricity / Water / Oil / Steam

The cavities and internal machined channels are available inside each roll to accommodate the heater cartridges and allow the heating/cooling medium to circulate. The thermocouples measuring the roll temperatures are located very close the the surface of the rolls. The electric heating module is controlled by PID with self-turning function.The wires inside and outside the rollers are connected by conductive slip rings to ensure stable rotation.

You are allowed to flexibly choose whether to configure the heating and cooling functions as per needs, which can help you maximize cost savings. For standard models, our lab two roll mixing mills comes in electric heating device to heat the rolls as high as 300 degrees Celsius and allows the circulating water to cool down the rolls under control. 3-zone electric roll heating is optional. If configured, three zones at the center and ends of the roll are individually heated and controlled to reduce temperature variance and obtain a more uniform processing temperature over the entire roll surface.

In addition, roll heating by steam is also available if required.

3-zone electrical roll heating(optional)

If you want better temperature uniformity as low as ± 0.5 degrees Celsius over the roll surface and obtain faster heating and cooling rates, we can equip your open mill with a separate oil circulation temperature control machine using oil heating & cooling to achieve more accurate and fast temperature control purpose.

Alternatively, if your material is prone to heat generation and has high requirements for cooling speed, we can equip the mill with an industrial chiller to provide cooling water below room temperature. When needed, you can let the low temperature water flow through the rolls to make it achieve the purpose of cooling down the material quickly.

Oil circulation temperature control device (optional)

Industrial water chiller (optional)

Side Platens

Each mixing mill is equipped with a side platen on each end of the two rolls to allow the smaller batch materials to be processed. The side platen is made of Teflon to excellent high temperature and corrosion resistance.

You can adjust the working width by moving them horizontally after loosing the retaining screws. The vertical height of the platens can be adjusted by screws as per material thickness. Both platens can be removed for easy cleaning.

Teflon side platen

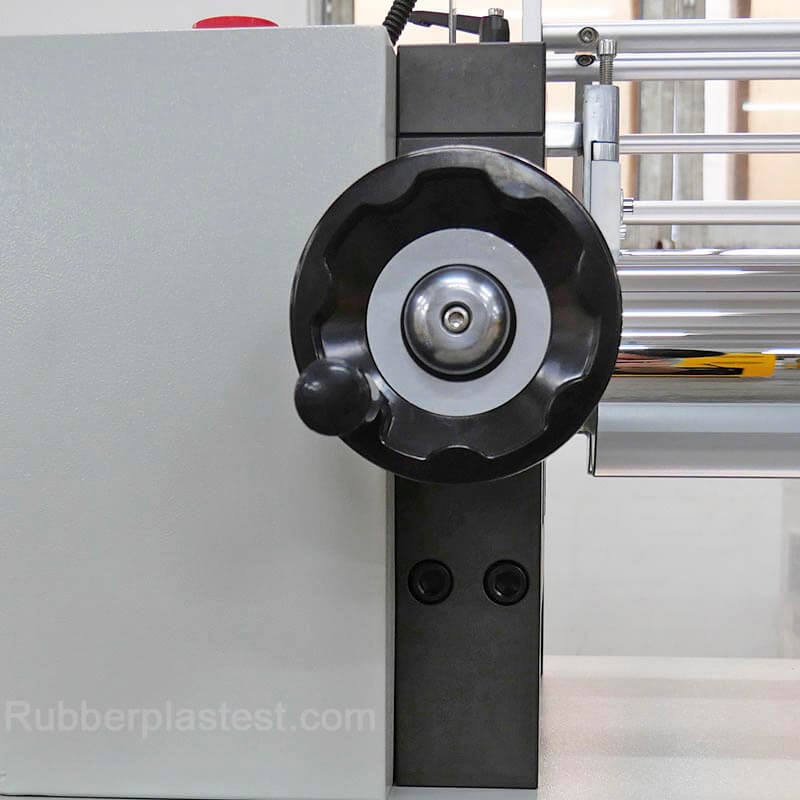

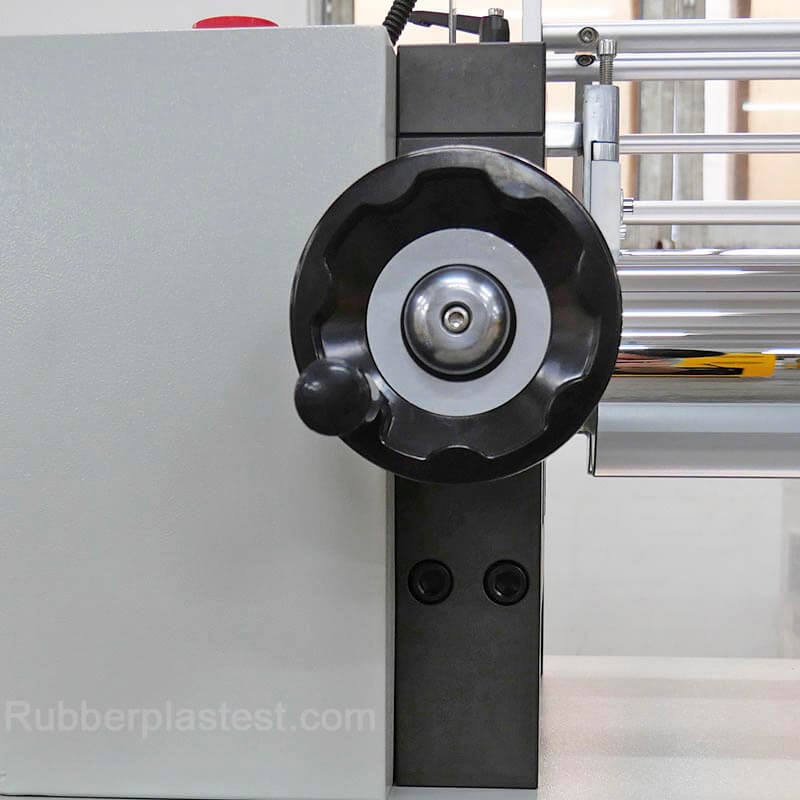

Adjustable Roll Nip by Manual / Electric

A mixing mill’s two rolls are arranged parallel to each other. When in operation, the roll facing you is called the front roll, and the other roll is called the rear roll.

You are available in moving the front roll forward and backward in the horizontal direction to achieve the roll pitch adjustment by turning the nip-adjusting handwheels on both sides of the roll. Two roll gap indicators next to the handwheels are available to present the pitch with specific numbers to the nearest 0.1 mm. The roll spacing on the left and right sides must be adjusted to the same.

If you are fed up with gap adjustment with hands, we can add an motorized roll pitch adjustment device to the machine based on PLC and LCD touch screen. It allows you directly input a desired gap value on the touch screen and then activate the corresponding control components for automatic adjustment and control. When other influencing factors are fixed, the relationship between roll gap and shear force is inversely proportional, that is, the smaller the roll gap, the greater the shear force.

Roll nip adjustment handwheel

Stable & Reliable Drive System (Single / Dual Motor)

We equip the Lab two roll mills with three-phase asynchronous AC motor(s) from internationally renowned brands. It guarantees large torque, stable speed, good braking performance. The chain is adopted as the transmission device to enhance the efficiency and stability. With the help of frequency converters and gears, the roll rotation speed can be controlled easily.

We equip the Lab two roll mills with three-phase asynchronous AC motor(s) from internationally renowned brands. It guarantees large torque, stable speed, good braking performance.

The chain is adopted as the transmission device to enhance the efficiency and stability. With the help of frequency converters and gears, the roll rotation speed can be controlled easily.

Single motor drive

Dual motor drive

Fixed / Adjustable Friction Ratio

When the machine is running, the rear roll rotates faster than the front roll. Alternatively, the front roll rotates faster then the rear roll. The speed difference between the two rolls is called the friction ratio or speed ratio. The friction ratio generates shear force on the material. When other influencing factors are fixed, the relationship between friction ratio and shear force is proportional: that is, the greater the speed ratio, the greater the corresponding shear force.

At AmadeTech, you are allowed to customize a fixed friction ratio yourself or choose a dual-frequency machine with a variable friction ratio function for flexible adjustments if required (refer to the Drive system chapter). As excessive friction ratio will cause the material to generate much heat during processing, you need to select an appropriate speed ratio for processing according to your material characteristics.

Fixed Speed / Synchronous / Asynchronous Variable Speed Control of Rolls

When other influencing factors are fixed, the relationship between rolling speed and shear force is proportional: that is, the greater the roll speed, the greater the corresponding shear force.

AmadeTech offers 3 options for roll rotation speed : Fixed Speed / Synchronous / Asynchronous Speed Control. The roll speed of an open mill with a fixed speed can’t be adjusted.

But if you choose a double-frequency machine, the speeds of the two rolls can be adjusted independently and asynchronously without affecting each other by means of two frequency converters. That is to say, the friction ratio of the two rolls can be adjusted at will according to the use. For a single-frequency machine, the revolution speed of the mixing machine can be freely adjusted within a range, and the speed of the front and rear rolls will change synchronously when you adjust the speed by means of a frequency converter.

Two frequency converter

Individual control of each roll

Easy-to-use Control Panel (Push-button /PLC Touch Screen)

AmadeTech configures the plastics & rubber mixing mill with a microprocessor-based physical button operation panel or Siemens PLC-based touch screen control panel. For conventional models, we believe that the physical button controller can already meet the needs of operation. The panel is covered with necessary buttons, knobs and digital meters, allowing you to conveniently control the machine, set temperatures of the rolls, and adjust roll speed, etc.

The preset temperature, real-time temperature, rotation speed and real-time revolution speed of the two rolls are displayed on the displays for you to monitor.

If you want to add more advanced functions such as showing the dynamic running state of the rolls, automatic roll nip adjustment or automatic scraping, a PLC and a touch screen are required to be configured, which enables you to touch the screen with your fingers to give instructions, otherwise these functions cannot be realized.

Push-button panel

LCD touch screen

Diverse Safety Features

All of our lab two roll mixing mills are equipped with multiple emergency stop switches on the top of the equipment where the operator’s hands are easily accessible. When any one of these switches is pressed in unexpected situations, the rolls will immediately stop revolving to relieve or reduce the hazards. The knee activated doors at the front and rear sides of the mill are available. You only needs to lift your knee touching against either door and the machine will stop immediately and reversely rotate no more than 1/4 of the roll circumference. Each of our machines is fitted with a pair of pivoted protection cages over the rolls to prevent your hands from being drawn into the roll pitch. There is a stop bar over the front roll with an emergency stop function when pushed with a hand.

Emergency stop buttons & bar

Knee activated door

Hydraulic quick opening units for emergency(optional)

Automatic scrapper(optional)

In addition, if you have more extreme requirements for safety, we can install an additional rear roll ejection device. The system consists of two additional hydraulic units located on outer side of the rear roll. When the emergency stop device is triggered, the rear roll will be immediately and automatically separated from the front roll to ensure that the operator’s hands are out of danger without further burns or squeezes. It is particularly worth mentioning that during mixing, ordinary machines require you to use a scraper knife to constantly cut, fold and roll the material on the front roll, which is tiring for users. If you want to free your hands and ensure consistency in material processing, we can directly configure your mill with an automatic scraping system under PLC control. It allows you to set the starting point, travel distance and end point for the rollover device in advance, and it can automatically travel to and from between two ends of the front roll at a specified speed to turn over the material instead of manual operation. All real-time dynamic operation status will be displayed on the LCD screen. These features greatly saves the operator’s time and reduce the safety hazards.

Lab Plastics & Rubber Mixing Mill Videos

PLC touch screen two roll mill

Rubber Mastication Video

Push-button lab two roll mill

Lab Plastics & Rubber Mixing Mill - Technical Specifications

| Model | R7024-120 | R7024-160 | R7024-200 | R7024-230 | R7024-250 | R7024-X |

| Roller diameter | Ф120 cm | Ф160 cm | Ф200 cm | Ф230 cm | Ф250 cm | customized |

| Roller length | 350 cm | 350 cm | 520 cm | 520 cm | 630 cm | customized |

| Roller Hardness | 50 ~ 60 HRC | |||||

| Roller temperature | Ambient temperature ~ 300°C | |||||

| Heating mode | Electrical heating / oil heating / steam heating (optional) | |||||

| Temperature accuracy | ±2°C (Electrical heating) ±1°C (Oil heating) | |||||

| Cooling mode | Water-cooling (optional) | |||||

| Roller speed | 0 ~ 30 RPM | |||||

| Speed ratio | Customized | |||||

| Roller Rev. | Constant speed/Single FM/Double FM (optional) | |||||

| Roller gap | 0.1 ~ 12 mm adjustable | |||||

| Control mode | Microcomputer/PLC | |||||

| Power supply | 3∮ 380 V, 50~60 Hz | |||||

Principle and Processing of Rubber Mastication & Mixing

The two rolls rotate relative to each other at different linear speeds. When the rubber material are fed, it will be drawn into the roll gap under the action of friction and adhesion while being squeezed by the rolls, forming a wedge-shaped strip. Under the effect of speed gradient and roll temperature, the rubber material will be further subjected to strong rolling, tearing and shearing, accompanied by oxidative fracture of the rubber molecular chain. The material in sheet discharged from the roll gap is wrapped on one roll due to the difference in roll surface speed and roll temperature, and then returns to the gap between the two rolls. The whole process is repeated several times until the desired processing state is obtained.

During mastication, the internal macromolecular chains of rubber are continuously stretched and broken, causing the molecular chains to change from long to short and the elasticity to change from high to low. During mixing, the surfaces of each component of the rubber compound are constantly updated, and the compounding agents are continuously and evenly dispersed in the raw rubber to achieve uniform compounding.

Lab Plastics & Rubber Mixing Mill Features

- The load frame is made of rugged steel and the surface is treated with baking varnish.

- KDB material used for roll fabrication.

- Occupies a small area and is easy to move.

- Can accept various polymer materials in different types.

- Fitted with a pair of side platens on both ends of the roll to flexibly control the effective processing width.

- Rolls can be heated by electric, oil and steam.

- Optional with 3-zone electric roll heating.

- Rolls are cooled using circulating cooling water.

- The roll nip is adjustable by hand or motor.

- Fixed roll speed, synchronous roll speed adjustment and independent roll speed adjustment of each roll are available.

- Fixed friction ratio and variable friction ratio are available.

- Key operation panel and touch screen are available.

- Equipped with a variety of emergency stop devices.

- Various high-end customizations as per user requirements are available.

FAQs about the Lab Plastics & Rubber Mixing Mill

The main applications of laboratory two roll mills are in the rubber and plastics industry.

The first function of the laboratory rubber mixing mill is mastication. Before rubber is mixed, it often needs a mastication process to break its long molecular chains to increase fluidity and plasticity, which facilitates even dispersion and mixing of various additives later. After the mastication is completed, we need to use an open mill to mix the various ingredients to complete the mixing. During the mixing process, fillers, such as carbon black, and other additives need to be added, and finally there is a sulfur addition process.

Why do we use an two roll mill to add sulfur? Often a lot of mixing is done with an internal mixer because it works more efficiently, but the internal mixer will squeeze and shear the materials intensely during processing and cause the temperature of the rubber materials to rise higher. When the temperature is relatively high, if we put a vulcanizing agent such as sulfur in, it will result in vulcanization in advance, which is also called scorch, which is not allowed to happen. So we need to take the rubber materials out of the internal mixer and put it on the open mill rolls to continue processing. This has two purposes: one is to lower the temperature of the material, and the other is to use an open mill to add the vulcanizing agent to the material and mix it evenly to prepare the material for vulcanization later in the vulcanization tank or vulcanizing press.

The function of the laboratory plastic two roll mill is to use high-temperature rolls and shearing force generated by the two rolls to mix and plasticize the mixture containing resin and various additives to disperse it evenly, promote mutual penetration and absorption between the components, and finally obtain the desired thickness of sheet material for further comparison and testing.

The temperature of the roll also has an important impact on the quality of the mixed rubber. When mixing with an open mill, the temperature of the rolls will continue to change due to the shear friction and heat generation of the rubber material. Different rubber materials, the temperature requirements of the rolls during mixing are also different, so the temperature of the rolls must be controlled at all times during mixing. Usually, the roll temperature is controlled by cooling water. The flow rate of the cooling water needs to be adjusted appropriately. If the flow rate is too large or too small, the roll temperature cannot be effectively controlled. During the mixing process, the temperature of the rolls surface should be constantly monitored and the temperature should be controlled within the allowable deviation range. The allowable deviation of the mixing roll temperature of the two roll mill is ±5°C. The roll temperature requirements when mixing different rubber materials are shown in the table below.

| Rubber Type | Front Roll Temp. (°C) | Rear Roll Temp. (°C) |

| Natural rubber | 55 ~ 60 | 50 ~ 55 |

| SBR | 45 ~ 50 | 50 ~ 55 |

| CR | 35 ~ 45 | 40 ~ 50 |

| IIR | 40 ~ 45 | 55 ~ 60 |

| NBR | ≤ 40 | ≤ 45 |

| BR | 40 ~ 60 | 40 ~ 60 |

| EPDM | 60 ~ 75 | About 85 |

| CSM | 40 ~ 70 | 40 ~ 70 |

| FPM23-27 | 77 ~ 87 | 77 ~ 87 |

| ACM | 40 ~ 55 | 30 ~ 50 |

Among the types of roller surface treatments selected by AmadeTech’s open mills, mirror rollers, electroplated rollers and matte rollers are the most commonly used.

Mirror rollers are the most commonly used rollers in lab two roll mills. Because they are processed by mirror polishing, they have a high surface finish and excellent flatness, and can reflect light like a mirror. Mirror rollers have very little adhesion to materials when processing materials, and are very suitable for mixing various thermoplastics, which can ensure the uniformity and gloss of materials during processing. Mirror rollers are chrome-plated before polishing and grinding. Since the chromium layer is relatively stable in different environments and is not easy to produce chemical reactions, it is difficult for acid and alkali solution gases to corrode the surface of mirror rollers. Good cleanability is also one of the characteristics of mirror rollers. The surface of mirror rollers is smooth and has a low friction coefficient, and dirt is not easy to accumulate on the surface of mirror rollers. Therefore, it is usually convenient to clean mirror rollers, which can save the maintenance cost of mirror rollers.

Electroplated rollers refer to rollers with a layer of metal or alloy material electrochemically plated on the surface of the roller. The most common open mill rollers are chrome-plated rollers. Electroplated rollers can improve the hardness and wear resistance of the roller surface and extend its service life. The surface smoothness and finish of electroplated rollers are not as good as those of mirror rollers, but better than matte rollers. It can be used for plasticizing and mixing thermoplastics as well as rubber materials.

The surface of the matte roller is sandblasted by an advanced fully automatic sandblasting machine, so its surface roughness is the highest among the three. It has strong surface adhesion and is not suitable for processing plastic materials. It can only be used to masticate or mix rubber materials. The rough surface of the roller can help break up particles and adhesives in the rubber material and improve the diffusion and plasticity of the rubber material.

The frequency regulator is used to adjust and control the rotation speed of the rolls. It can be seen from the words that the single-frequency lab two roll mill machine is equipped with only one frequency converter, while the dual-frequency frequency machine is equipped with two frequency converters. When a frequency converter adjusts the speed, it means that the speed of the two rolls will change at the same time. Therefore, the speed ratio of the two rolls is fixed and cannot be changed, which is determined by the structure of the machine. The control of the two rolls of the double frequency modulated machine is independent of each other and does not interfere with each other. They are driven and controlled by two independent motors, transmission devices and frequency converters. When the machine is working, you can set the speed of the front roller greater than the speed of the rear roller according to the material characteristics or processing needs. You can also set the speed of the rear roller greater than the speed of the front roller to achieve free setting of the speed ratio. This greatly facilitates the operation of the machine and expands its application scope.

Due to the difference in structure, the cost of a dual-frequency open mill is higher than that of a single-frequency machine. If you have sufficient budget, we recommend that you directly choose dual-frequency modulation lab open mill to meet your current or wider needs in the future.

First of all, try to use an open mill with a roll whose inner cavity is machined and drilled, so as to reduce its thermal resistance and improve the cooling effect.

Secondly, strictly control the initial temperature of the cooling water. When the initial temperature of the cooling water is 10 ~ 14°C, the cooling effect of the roll is much better. However, low-temperature water like this often requires the use of underground water or refrigeration to obtain it, and additional corresponding equipment is required. When tap water or river water is usually used, especially in summer, water with an initial temperature lower than 25°C should be used for cooling as much as possible. Otherwise, the cooling effect will be significantly reduced and may not even meet the process requirements.

Thirdly, keep the inner cavity of the roll clean, and try not to use cooling water containing salt minerals to avoid precipitation and affect the cooling effect. It is best to clean the dirt inside the roll regularly.

Roll speed, speed ratio and roll gap are several important working parameters of the open mill. They should be selected according to the nature of the processed materials, process requirements, production safety, mechanical efficiency and labor intensity, and are generally determined by experience.

Roll speed is the linear speed of the roll when it rotates. Generally, the higher the roll speed is, the greater the shear force generated when the roll rotates.

The speed ratio is the ratio of the linear speed of the two rolls. It is generally expressed by the ratio of the linear speed of the rear roll to the linear speed of the front roll. For the convenience and safety of operation, the linear speed of the front roll is generally smaller than the linear speed of the rear roll. The specific roll speed ratio is selected based on the technological requirements for processing materials. Open mills with different uses also require different roll speed ratios. Generally, the larger the speed ratio, the greater the shear force generated when the drum is working.

The roll gap is the distance between the two rolls, which can be adjusted manually or electrically according to processing needs. When the roll pitch is reduced, the speed gradient will increase, the shear force will increase, and the rubber mixing effect will be better. However, when the roll gap is too small, the temperature of the rubber material will rise sharply, which will affect the processing effect. Therefore, the roll gap should not be too small during operation.

- Labor protection equipment must be put on before starting the machine.

- Check whether the fasteners of themachine are loose or damaged.

- Check whether the emergency stop device is intact, effective and sensitive. It is strictly prohibited to use the emergency stop device during normal stopping.

- After the problems found during the inspection are eliminated, start the machine.

- The heating and cooling of the rollsmust be carried out slowly while the rollsare rotating to prevent cracks or even breakage due to temperature stress caused by local temperature sudden changes in the rolls.

- Adjust the roll distance to be consistent on the left and right to avoid damage to the rollsand bearings. When reducing the roll distance, care should be taken to prevent the two rolls from scratching the roll surface due to collision.

- During the rubber mixing process, rubber mixing tools andrelevant itemscannot be piled on the machine to avoid tools falling into the machine and causing damage to the equipment. When the machine is running, if the rubber is found to be stagnant at the roll gap, do not press it with your hands. When pushing the rubber with your hands, you can only push with your fist to prevent your hands from being caught by the rolls.

- After braking or a sudden power outage, the rubber material in the roll gap must be removed before driving. It is strictly prohibited to start with load.

- It is strictly prohibited to use the machine when it is overloaded for a long time or when the safety protection device fails.

The roll materials of early two roll mills were all made of cast iron. In the later period, it was updated to chilled cast iron. The difference between chilled cast iron and cast iron is that some chilled alloys are added to cast iron. Their advantages are particularly good wear resistance and relatively high hardness. Generally speaking, its hardness converted to our current HRC standard is about HRC50. There is no problem in processing rubber with rolls made of this material. It was cast in advance and left with a hollow hole. But the disadvantage of this material is that once you want to configure it with a heating function, its internal processability is particularly poor. When we need a roll with heating function, we have no way to use cast iron or chilled cast iron. Moreover, these similar materials are difficult to weld using existing processes.

Therefore, we will consider using some high carbon steel to complete the drum production. Because high carbon steel has excellent processability and weldability, it is convenient for us to perform necessary processing and assembly inside the roll. But relatively speaking, the corrosion resistance and wear resistance of high carbon steel may be a little worse. Therefore, after we process the high carbon steel into the characteristics and shape we want, we also need to do some electroplating processing. So it is also called electroplating roll.

The above is the difference between chilled cast iron rolls and electroplated rolls. If you use an electroplating roll to make some particularly thin materials, the electroplating roll itself may have insufficient adhesion. At this time we may need to use a third material, which is alloy steel roll. The advantage of alloy steel roll is that it combines the advantages of chilled cast iron and high carbon steel, but its disadvantage is that the price is relatively high.

More often than not, we have to choose roll materials based on actual usage needs. From a certain perspective, The most expensive roll material does not represent the better. For example, if you use an alloy steel roll, its corrosion resistance is actually not as good as that of an electroplated roller, but its wear resistance and other properties are better than that of an electroplated roll. In a word, the most suitable one is the best, not that the most expensive one is the best.

If the order of adding ingredients during rubber mixing is inappropriate, it may cause uneven dispersion of the ingredients, or lead to scorching, derolling or over-mixing. Therefore, the order of adding ingredients is one of the important factors related to the quality of the mixed rubber.The order of adding additives during rubber mixing should follow the following principles:

- The compounding agent with small dosage and high effect shall be added first.

- Compounding agents that are difficult to disperse in the rubber compound, such as zinc oxide and solid softeners (paraffin, rosin, resin, etc), shallbe added first.

- Compounding agents with low critical temperature, high chemical activity, and temperature sensitivity should be added later.

- Vulcanizing agents and accelerators should be added separately.

The general feeding sequence for natural rubber mixing with an two roll mill is:

Raw rubber (plasticized rubber, masterbatch, reclaimed rubber) → solid softeners → small additives (accelerator, activator, antioxidant, anti-scorch agent, etc.) → fillers (carbon black, clay, calcium carbonate, etc.) → liquid oils (paraffin oil, naphthenic oil, aromatic oil, etc.) → sulfur.

This feeding sequence can also be used for traditional internal mixer. When the amount of liquid softener is small, it can also be added before the filler. If the amount of filler and oil is larger in the synthetic rubber formula, the oil can only be added after the filler or added in batches alternately with the filler. For some special formulas, the order of adding agents can be adjusted appropriately. For example, hard rubber contains a large amount of sulfur and it should be added before other ingredients to ensure uniform mixing. When mixing sponge rubber, oil should be added after adding sulfur. When mixing nitrile rubber, since sulfur has poor compatibility with nitrile rubber and is difficult to disperse, sulfur should be added before various compounding agents. If there is white carbon in the formula, the white carton should be added in batches after adding rubber and before other ingredients to ensure that the white carton is evenly dispersed.

The process methods of rubber mastication in an open mill include tightmilling mastication, one-time mastication, segmented mastication, and mastication with the addition of chemical peptizers.

The tightmilling mastication method is to pass the raw rubber through the roll gap with a roll pitch of 0.5 ~ 1 mm, and directly fall on the material receiving tray without wrapping the roll. The operator needs to repeat the tightmilling procedure for a specified number of times or time until the required plasticity is obtained. The number of processing depends on the plasticity requirements of the rubber material. The higher the plasticity requirement, the more times are required. The tightmilling method enables the rubber material to dissipate heat quickly, have better cooling effect, uniform plasticity and high quality.

The one-time mastication method is also called the wrap-roll mastication method. The raw rubber is wrapped in a roll with a larger roll gap (5-10 mm) and then continuously passed through the rolls for mastication until the specified time is reached. There is no parking during the plasticizing process, and the knife is cut multiple times to facilitate heat dissipation and obtain uniform plasticity. This method has a shorter mastication time, is easy to operate, and has low labor intensity, but the mastication effect is not ideal and the plasticity is not uniform enough.

The segmented mastication method is an effective method used when the plasticity requirements of the masticated rubber are high and one-time mastication or tightmilling mastication cannot achieve the purpose. First, the raw rubber is masticated for a certain period of time, such as 15 minutes, and then discharge the rubber to cool for 4 to 8 hours, and then the second mastication is performed. Repeat the above steps several times until the required plasticity is reached. According to different plasticity requirements, the whole process can generally be divided into two stages or three stages of plasticizing. This method of mastication has high production efficiency, and the plasticity of the masticated rubber is high and uniform, so it is widely used in production.

The chemical peptizer mastication method is based on the above-mentioned tightmilling mastication method and one-time mastication method, and adds a chemical peptizer for mastication. It can improve the mastication efficiency and shorten the mastication time. For example, if 0.5 parts of accelerator M is used for natural rubber, the mastication time can be shortened by about 50%. It can also reduce the elastic recovery and shrinkage of the masticated rubber.

| Quality problems | Causes | Solutions |

| Plasticity is too low | The plasticizing time is short The roll distance is large The plasticizing temperature is too high The chemical plasticizing agent is not added or the amount is insufficient. | Adjust mastication conditions (time, temperature, roller distance) Increase mastication, and check the use and dosage of chemical plasticizers |

| Plasticity is too high | The mastication time is too long The initial viscosity of the raw rubber is low, and the amount of chemical peptizer is too much | Adjust the mastication time and reduce the amount of chemical plasticizer |

| Plasticity is not uniform | The loading capacity is too large The mixing is uneven, and the chemical peptizer is unevenly dispersed. | Reduce the filling capacity Perform additional mastication, and prepare the chemical peptizer into a masterbatch for use |

The rubber processing capacity refers to the quantity of rubber mixed by the open mill at one time. Whether the capacity of the open mill is reasonable not only affects the production capacity, but also affects the quality of rubber mixing. If the capacity is too low, not only the production capacity will be reduced, but also unstable operation will occur on the open mill rolls. If the capacity is too high, the rubber material can only shake and suspend above the two rolls but cannot enter the roller gap. A reasonable capacity can be determined based on the rubber material covering the whole front roll and accumulating a certain amount of rubber material between the two rolls. Generally it can be calculated according to the following formula:

q=KDL

q is the single processing capacity, in dm3

D is the roll diameter, in cm

L is the length of working part of the roll, in cm

K is the experience coefficient, K=0.0065 ~ 0.0085

Since the linear speeds of the two rolls are different, the rubber material has a speed gradient in the roll gap. The rubber material in contact with the surface of the rear roll that rotates faster passes through the roll gap faster, while the rubber material in contact with the surface of the front roll passes through the roll gap at a slower speed, so that there is a speed gradient between the rolls.

When the roll speed increases, the friction ratio increases, and the roll spacing decreases, the speed gradient will increase, and the shear deformation and mechanical damage to the rubber will be greater, thereby reducing processing time and improving mechanical efficiency. However, when the speed and friction ratio are too large, the temperature of the rubber material will increase due to frictional heat, which will reduce the plasticizing effect of the raw rubber and even cause the rubber compound to scorch. Therefore, the velocity gradient must be limited so that it does not exceed the allowable temperature limit of the material, and cooling must also be enhanced.

The water cooling or heating function of the open mill is often related to the materials we process and the current temperature in the laboratory. Rubber is widely used in the polymer industry, and some materials are very soft and some are very hard.

During the process, the relative motion of the two rolls at different speeds will cause squeezing and shearing of the material, causing the material to generate heat. Especially when the vulcanizing agent is added during mixing, we must strictly control the chemical reaction between the vulcanizing agent and the rubber. In this process, in order to control the generation and spread of heat, we often need to pass cooling water into the rolls. After cooling, the purpose of preventing or minimizing the vulcanization reaction of the rubber material can be achieved.

However, for some materials that are relatively hard in nature, if your temperature is too low, the material will be very hard and difficult to shear and disperse, such as fluorine rubber. Under low temperature conditions, you cannot easily cut and knead it, and other processes such as adding various additives for mixing are also difficult to complete. Therefore, when we process this type of material, we must first heat the material. If we want to raise the temperature, we must have a heat source, so we need to equip the rolls of the open mill with a heating function to easily achieve the purpose of heating the material.

- Heating of raw rubber: Re-processthe masticated raw rubber in the two roll mill machine to enable heating and softening, and add other polymers for mixing.

- Addingcompounding agents: generally add softeners, stearic acid, etc., and then add powder and carbon black (carbon black can also be mixed with part of the raw rubber separately in advance to form a masterbatch). Sulfur is usually added at the end of mixing stage or during the second re-mixing after suspending the rubber compounding for a period of time.

- Removing the rubber sheet after even dispersion: When all the ingredients are added, continue mixing to mix evenly and remove the rubber sheet.

In our daily use of lab two roll mills, when we compare pigment formulas, if the rollers are not cleaned cleanly, it will lead to inaccurate color presentation. When we do the stabilizer test, if the cleaning is not done well, the aging effect of the material will also be bad. The reason for these bad consequences may be the residue of the last test material on the surface of the roll or the existence of carbonization points. When this happens, what we need to do most is to clean the rolls deeply.

Before doing in-depth cleaning, we need to prepare some tools, including a bamboo scraper, low-melt and low-viscosity general materials such as LDPE, additives such as sand wax, and auxiliary tools such as cotton cloth.

When the roll of the two roll mill is running normally without load at normal processing temperature, it is recommended to apply the sand wax to the surface of the roll, spread it evenly with cotton cloth and spread it over the entire roll, and then wipe it again clean. You can also melt the LDPE between the two rolls, then scrape and clean it repeatedly with a bamboo scraper. After a period of time, the rolls will become very clean. For some carbonized spots, we recommend using a cotton cloth dipped in wax to rub these areas repeatedly to make the roll surface clean enough. For some materials that like to stick to the rolls, we tend to set a temperature above the processing temperature, choose some plastics with low melting index, and put these plastics on the rolls to process and gradually dilute the original materials.

- When operating the machine, keep the surface of the machine and the surrounding environment clean to avoid inserting hard debris into the rubber material and damaging the rolls and the machine.

- The lubricating parts must be regularly supplied with sufficient lubricating oil as required. The oil level of the reducer should be checked regularly to see whether the oil level is normal, and whether the instruments, signaling devices, switches, etc. are sensitive and reliable. If they do not meet the requirements, they must be replaced immediately.

- If abnormal vibrations and sounds occur during operation of the equipment, stop immediately and contact maintenance personnel for inspection and repair.

- Frequently check the temperature of various parts, such as roll bearing and motor bearing. Temperature abnormalities should be checked and find the causes.

- After the machine is finished working, the power, water source should be turned offand the switches should be reset, and the rolls and machine surface should be cleaned.

Get a Customized Quote for a Lab Plastics & Rubber Mixing Mill that Best Meets Your Needs

Tell us about your unique testing requirements to get a personalized solution from AmadeTech

Related Products

Related Posts