Hands-free Two Roll Mill with Automatic Scraper

Model

AT-R7024 series

Applications

Used to plasticize and mix various resin polymers such as PVC, PP, PE, pigments and additives in small batches for prototyping and sheet forming.

Standards

ISO 2393, ASTM D3182, etc.

Hands-free Lab Two Roll Mill Description

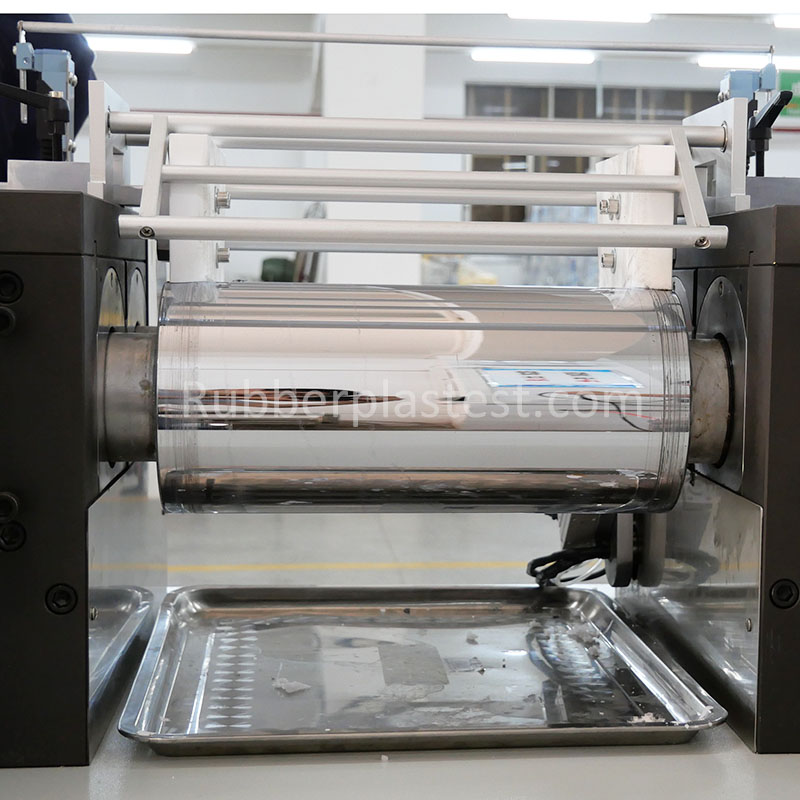

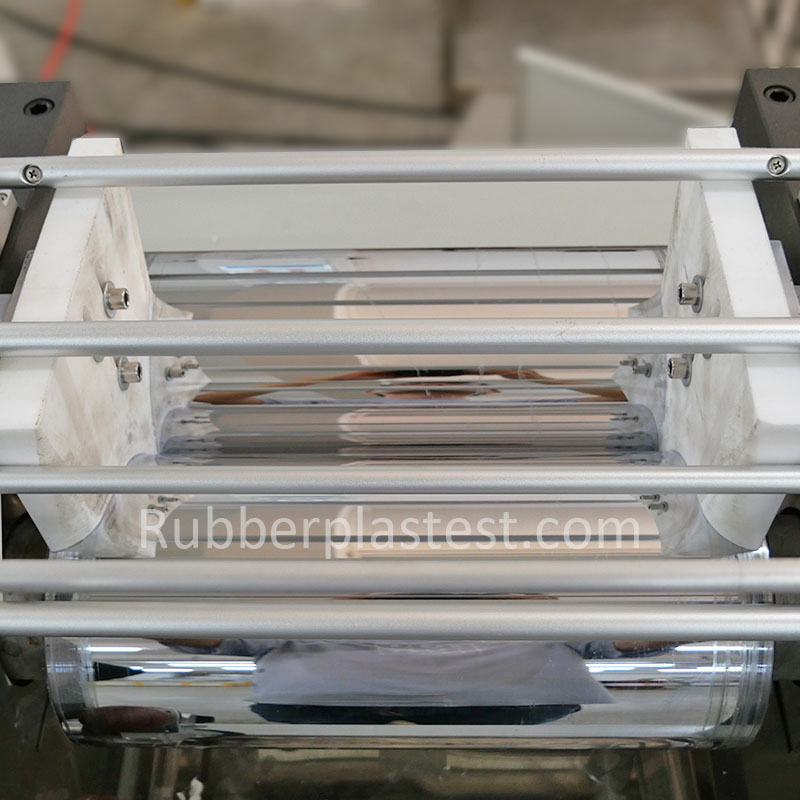

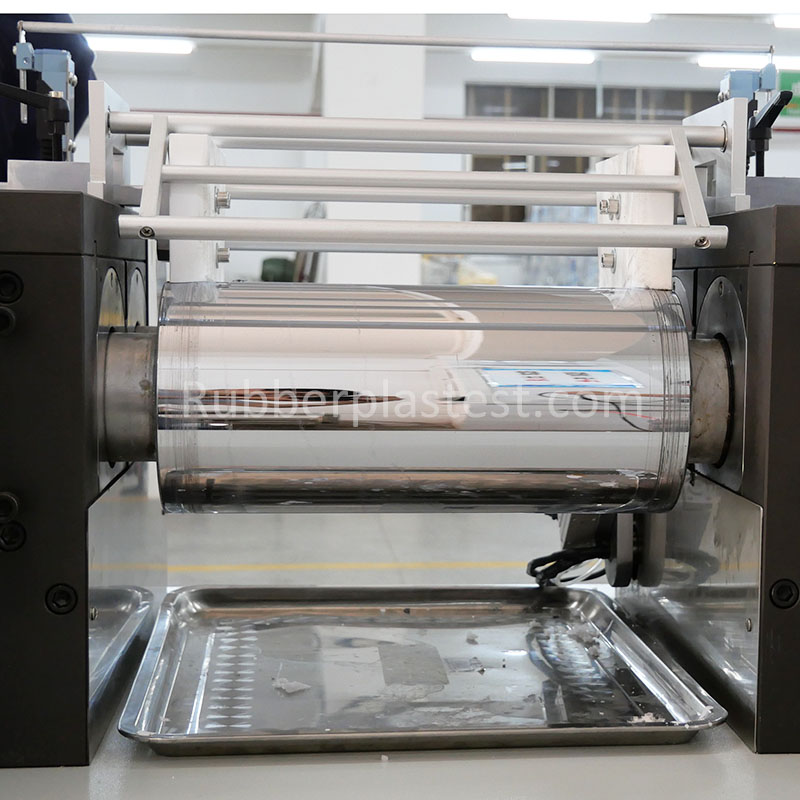

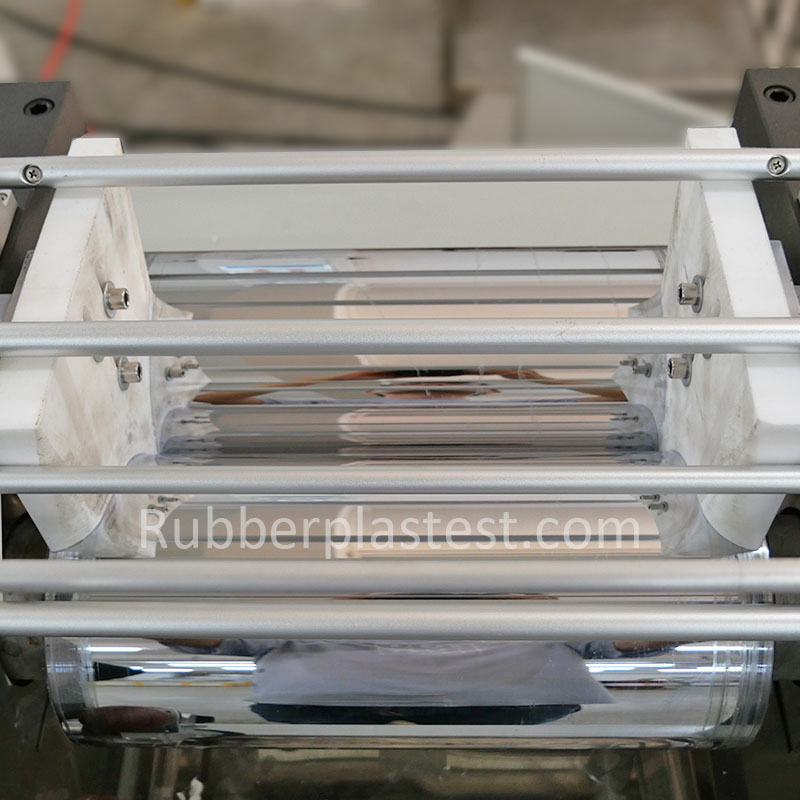

The hands-free automatic scraping lab two-roll mill is designed and developed on the basis of our standard lab open mills to compound plastic materials. It is featured with an automatic rollover device in front of the front roll for automatic material turning, thus freeing your hands during the mixing process and guaranteeing consistency of the final material from batch to batch. The rollover head is made of high-temperature and wear-resistant material in a conical shape to fit the front roll well. A DC motor built in the device is utilized to provide power and enable the head to forward and reverse rotate as required. The rollover device supported by two cylindrical shafts parallel to the front roll is capable of moving back and forth cyclically under control.

The control system consists of Siemens PLC and 10-inch LCD colour touch screen. You are allowed to set the starting position, length of travel, ending position and moving speed of the rollover device on the screen. When the rollover device moves to the preset starting position, the air cylinder works to push the rollover head forward to contact against the front roll, and the rollover device moves horizontally towards the ending position at the same time. While the whole rollover device moves, the rollover head rotates in the direction opposite to the direction of movement enabling the turning of the batch material wrapped around the front roll from one side to the other. When the rollover device moves to the preset ending position, the rollover head will immediately pop back and separate from the roll surface, then prepare to go back along the same route.

When the machine is in working condition, you can view the displacement position of the rollover head, running time, roll speed, roll distance parameters of the device directly from the screen. The mill stops automatically when the preset mixing time is reached. Alternatively, you can also disable the automatic scrapping device during mixing.

The two roll mill is equipped with an infinite variable speed drive of each roll allowing for adjustable roll rotation speed and variable friction rate. There are more optional features available to be configured if you want, such as oil heating and cooling, motorized pitch adjustment, roll ejections, etc. For more detail, please move to the page introducing the standard machines.

Automatic rollover device

Hands-free Lab Two Roll Mill Video

Hands-free Lab Two Roll Mill - Technical Specifications

Model | AT-R7024 series |

Operation mode | Automatic scraping |

Roll diameter | 120 mm / 160 mm / 200 mm / 250 mm and more |

Roll length | 350 mm / 520 mm / 630 mm and more |

Roll hardness | 50 ~ 60 HRC |

Roll surface treatment | Mirror / chrome-plated / matte |

Roll temperature | Room temp. ~ 300 °C |

Heating mode | Electrical heating / oil heating / steam heating (Optional) |

Cooling mode | Water / oil cooling (Optional) |

Friction ratio | 1.17:1 / 1.25:1 or customized / adjustable ratio |

Roll revolution | double frequency modulation |

Roll gap | 0.1 ~ 5 mm adjustable |

Control mode | PLC touch screen |

Optional features | Automatic roll ejection device |

Power supply | 3-phase, AC 380 V, 50 Hz or transformed to other voltages |

Hands-free Lab Two Roll Mill Features

- Equipped with automatic scrapping device to ensure all batches are processed under the same processing condition.

- Built up with rugged steel to make it completely self supporting.

- Different sizes of rolls with different surface treatments are available.

- Optional with electric Heating and oil heating for the rolls.

- Three-zones electric roll heating and control are available if required.

- Equipped with adjustable side platens.

- Configured with PLC-based LCD touch screen.

- Provides 3 types of drives: fix speed/synchronized speed change/asynchronous speed change with variable friction rate

- Equipped with stop bar, protection cages, Emergency stop switches, knee activated doors, etc safety features.

- Optional with motorized roll gap adjustment device and roll ejection device.

- User-friendly and easy to maintain.

Get Free Quote of Hands-free Laboratory Two Roll Mill that Best Meets Your Needs

Tell us about your unique testing requirements to get a personalized solution from AmadeTech

Related Products

Related Posts