Open-close Dispersion Kneader Machine

Model:

AT-R7030 series

Applications:

Used for mixing and kneading various polymers that are difficult to clean and expensive, high-hardness, easy-to-contaminate zirconia, alumina, ceramic powder, metal powder, cemented carbide materials etc.

Standards

ASTM D3182

ISO 2393, etc.

Open-close Dispersion Kneader Machine Description

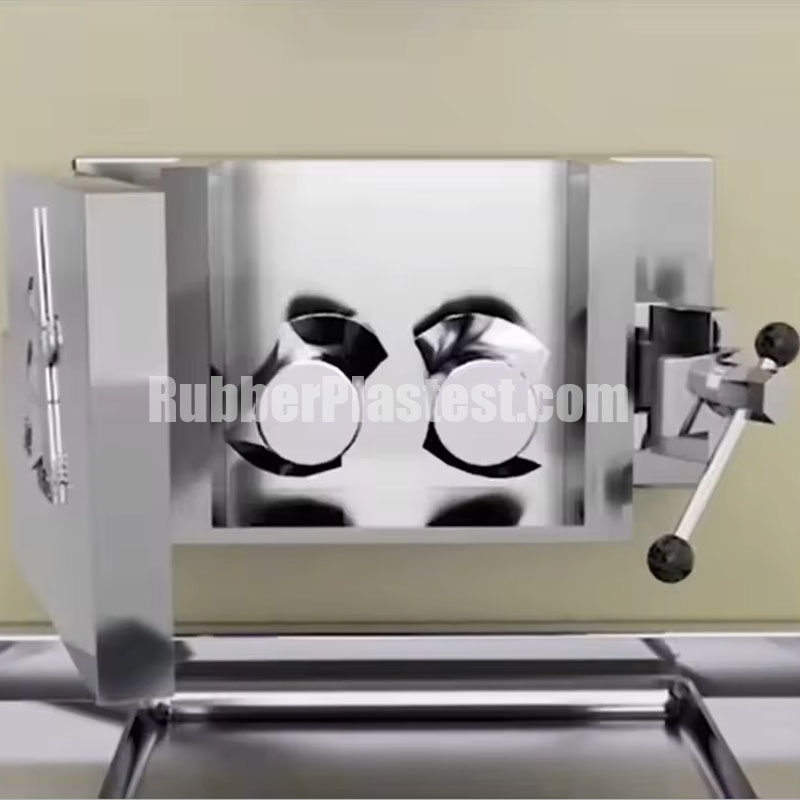

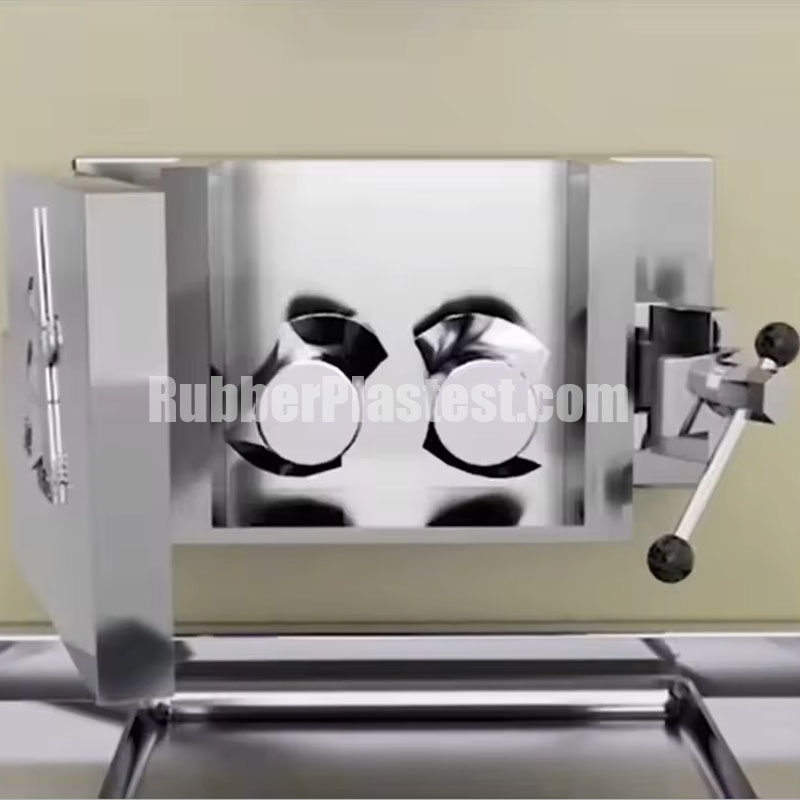

Compared with a ordinary laboratory internal mixer, the biggest feature of the Open-close type Dispersion Kneader Machine is that it has an open and close mixing chamber and the rotors are removable: The front plate and the walls on both sides and below of the mixing chamber can automatically pop outward one after another like a drawer under hydraulic drive, so that the two rotors are completely exposed to facilitate subsequent cleaning. In addition, you are available to remove and install the rotors freely by a hex wrench. When discharging, you only needs to place the material receiving tray under the rotors to catch the mixed materials. In this way, the material adhered to the equipment can be cleaned completely without dead ends and zero residue, which solves the problem of difficulty in cleaning, eliminating the possibility of mutual contamination in the processing of materials with different formulas. For example, ceramic powders such as zirconia and alumina are prone to stick to the surface of the rotor and the inner cavity, making them difficult to clean. If it is not cleaned up, it will have a negative impact on subsequent batches of products. Even for the same material it will have an adverse impact because there is less residual adhesive, which will cause defective products once it appears on the product surface.

Mixing chamber structure

The mixing chamber and rotor are made of SKD chromium-molybdenum alloy. After quenching and tempering heat treatment, the surface is polished and plated with hard chromium for super-hardening and super-wear-resistant effect. The bottom of the mixing chamber is “W” shaped, and the upper pressure ram is “M” shaped, forming a fully enclosed mixing chamber. The capacity of the mixing chamber can be freely selected from 1L to 5L according to processing needs. There is a precision heating device inside the mixing chamber wall that can provide a mixing temperature of up to 300°C for the materials being processed. The pressure ram as a chamber cover is connected to the piston head of the air cylinder. During operation, as the piston descends, the ram pressurizes the material from the top to strengthen the squeezing and shearing effect. There are cavities close to inner layers of the pressure ram and the chamber to allow water to pass. We equip these components with water inlet and outlet pipes so that tap water can continuously flow through the chamber walls to cool the material when needed.

The rotor mixing blade adopts a prismatic spiral design, which can relatively rotate inward at a fixed speed ratio to quickly shear and disperse the material to meet the physical property requirements. The drive motor of this machine adopts an internationally renowned brand to provide strong power and ensure excellent quietness, stability and durability. The machine’s human-machine interaction interface is a floating touch screen based on PLC. You can easily set parameters such process time, temperature and rotation speed by touching the virtual buttons on the screen, give instructions to the device to make it work, and monitor the machine’s data, and dynamic operating status in real time. If required, torque curves throughout processing can be presented on the screen to aid in judging the uniformity of the mix.

In addition, if you are mixing small batches of precious materials, we can provide smaller capacity such as 60ml, 200ml or 500ml split type internal mixer. Its biggest feature is that the cavity walls of the mixing chamber can not only be pulled apart, but also completely separated and removed for material cleaning. However, it does not support cooling function. If you have any special needs, please reach out to us for a flexible solution.

Open-close Dispersion Kneader Machine - Technical Specifications

Model | AT-R7030 series |

Mixing chamber volume | 0.5L/1L/3L optional |

Hardness of chamber and rotor | HRC60 |

Rotor and chamber structure | Can be removable |

Upper pressure of chamber | 0.5 ~ 0.8 MPa (connected to external air source) |

Cylinder ram diameter | 80 mm (AirTAC) |

Material discharging mode | Open-close |

Temperature range | Room temp. ~ 250 °C |

Heating mode | Electrical heating |

Cooling mode | Circulating water |

Rotor speed | 0 ~ 40 RPM adjustable (front) / 0 ~ 31 RPM adjustable (rear) |

Friction ratio | 1:1.39 (customizable) |

Controller | Siemens PLC touch screen |

Power supply | 3-phase, AC 380 V, 35 A |

Dimensions | 1150 mm (W) x 1300 mm (D) x 2400 mm (H) |

Open-close Dispersion Kneader Features

- The whole machine occupies a small area and saves space.

- The Chamber and rotor are made of high-hardness SKD chromium-molybdenum alloy, and the surface is polished and super-hardened, which has excellent wear resistance and corrosion resistance.

- The mixing chamber can be opened under control to expose the rotors, which facilitates unloading, changing and material cleaning.

- It is a very good choice to use it to process materials that are expensive or are afraid of contamination.

- Various mixing chamber capacities are available.

- The rotor is detachable, easy to operate and maintain.

- The spiral angle and working length of the rotor ridge are reasonably designed.

- The mixing shaft is leak-proof and adopts dry mechanical shaft seal.

- The rotor speed can be adjusted freely through the frequency converter.

- Comes with heating and cooling functions.

- The material is pressurized pneumatically to enhance the mixing effect.

- Human-machine interaction interface using PLC and touch screen.

- High production efficiency and uniform mixing of materials.

- The transmission system is smooth, precise and noiseless.

- Low failure rate, energy saving and cost saving.

- Easy maintenance and long service life.

Get a Customized Quote for a Open-close Dispersion Kneader Machine that Best Meets Your Needs

Tell us about your unique testing requirements to get a personalized solution from AmadeTech

Related Posts