Mooney Viscometer

Model

AT-R7001

Applications

Mooney Viscometer is also known as the Shearing Disc Viscometer. It is used to determine the Mooney viscosity, Mooney stress relaxation and pre-vulcanization characteristics of uncompounded or compounded rubbers.

Standards:

ISO 289, ASTM D1646, DIN 53523, BS903: part 58, ISO 3384, etc.

Mooney Viscometer Description

Mooney viscosity is expressed as the shearing torque required to rotate a cylindrical metal rotor embedded in rubber material within a cylindrical cavity. When rotor rotation is suddenly stopped, the torque on the rotor drops at some rate depending on the tested rubber and the temperature, which is called the “Stress relaxation”. The stress relaxation behavior of rubber is a combination of both an elastic and a viscous response. Pre-vulcanization characteristics are a measure of the time to the initial vulcanization and the rate of cure during the early state of rubber vulcanization, and scorch time is a core indicator to be measured.

A Mooney shearing disk viscometer consists of dies, die closure system, rotors, heating and temperature-measurement system, control software, etc.

Dies

Two dies forming the die cavity are fabricated from the exceedingly rigid steel to enable it to withstand the wear behavior of rubber compounds with different levels of viscosity during the test. The die cavity is 50.93 mm in diameter and 10.59 mm in depth. There are radial V-grooves spaced at 20° intervals and distributed on the upper and lower surfaces of the die cavity to prevent slippage when exerting force on the rubber. A round hole is available in the middle of the lower die for inserting the shaft of the rotor.

lower die

Die Closure

The lower die is stationary and the upper die can move down by pneumatic to close the dies with a force of 11.5 kN and maintained at this level throughout the test. In order to prevent the rubber from adhering to the mold cavity during the test and reduce subsequent cleaning time, we recommend inserting a layer of protective film between the upper and lower die surfaces and the rubbers in contact with them when mounting the rubber samples.

Die closure

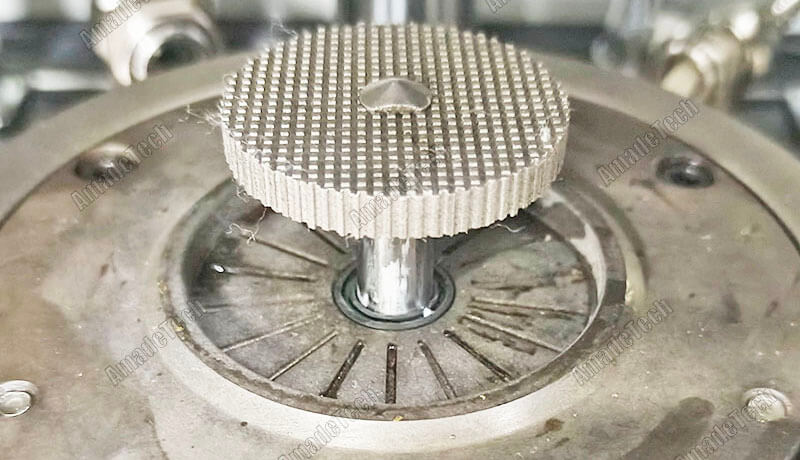

Rotors

A rotor is contained in the closed die cavity with its top and bottom surfaces 2.54 mm from the surfaces of the top and bottom dies during the test. The rotor material is the same as that of the dies, with an exceptional hardness and wear resistance. There are many serrations distributed on the face of the rotor according to the prescribed layout, size and spacing. A straight shaft is vertically fastened to the center of the rotor securely. When mounting the sample, the shaft needs to pass through the center of the disc sample first, and then be inserted into the round hole in the middle of the lower die. And the other disc sample is required to be placed on top of the rotor to wait for the closing of the die. A replaceable sealing rubber ring on the edge of the hole is provided to prevent rubber leakage.

We equip each Mooney viscometer with two rotor specifications. The diameter of the large rotor is 38.1 mm and the thickness is 5.54 mm. The specifications of the small rotor are the same as the large rotor except that the diameter is 7.62 mm smaller. When the test is started, the rotor will rotate in one direction relative to the mold at a speed of 2 rotations per minute. In addition, if a stress relaxation test is performed, the rotor can stop rotating within 0.1s. The signals when the rotor rotates are collected by the torque sensor in real time and sent to the data processing center for processing, and then displayed on the human-machine interaction terminal.

Rotors

Heating and temperature-measurement system

There are heating devices adjacent to the upper and lower dies to guarantee that die cavity heats up quickly and maintains the target temperature within the specified time. Two platinum resistance temperature sensors are built into the upper die and lower die respectively to acquire real-time temperatures. Temperature changes will cause changes in the resistance of the platinum thermal resistor, and changes in resistance cause changes in voltage. After 24-bit A/D conversion, the temperature signals are sent to the interactive interface for operators to monitor.

Measurement and control software

Each AmadeTech Mooney viscometer is equipped with a set of dedicated English software based on the latest Windows operating system to provide powerful support for testing. The software allows you to choose different test items including Mooney viscosity test and Mooney scorch test. You can complete all test operations on the software interface, including setting the test temperature, selecting the rotor type, monitoring the test status and viewing data feedback. The Mooney stress relaxation test is integrated into the Mooney viscosity test module, enabling automatic and seamless connection to start the Mooney stress relaxation test after the Mooney viscosity test is completed. Before the test, you only need to click the mouse to preset the warm-up time for one minute, the test time for 4 minutes, and the relaxation time for 1 minute. During the test, the viscosity curve, Mooney scorch curve, stress relaxation curve, and upper and lower die temperature curves are automatically displayed. You can customize to check the parameters you want to display in the test results and set the upper and lower limits of qualification, including the initial Mooney value, the Mooney value at the end, the maximum Mooney value, the relaxation end time, the Mooney value corresponding to relaxation end time, first vulcanization time point, second vulcanization time point, etc. The software supports you to output or print test reports in Excel, Word, PDF and other formats.

Test Interface

Principle of Mooney Viscometer Determination

A rubber sample wrapping a metal disc is located in a rigid cylindrical cavity kept at a specified temperature and pressure. The disc is rotated in one direction at a given speed for a specified time. The resistance offer by the rubber to this rotation is measured as the Mooney viscosity of the sample.

Principle of Stress Relaxation Determination

At the end of a Mooney viscosity test, the rotation of the metal disc is abruptly stopped and the rate of torque decrease over time is measured.

Principle of Pre-vulcanization Characteristics Determination

The viscosity of rubber compound sample is recorded during heating at a specified temperature. The minimum viscosity and the times for the viscosity to increase by specified amounts are measured and used as arbitrary measures of the start and rate of cure.

Mooney Viscometer Video

Mooney Viscometer - Technical Specifications

Model | AR-R7001 |

Temperature range | RT ~ 200℃ |

Temperature display resolution | 0.1℃ |

Temperature control accuracy | ± 0.3℃ |

Calibration accuracy | Mooney value ± 0.5 |

Rotor speed | 2 ± 0.02 RPM |

Die rotor | 38.10 ± 0.03 mm (large), 30.48 ± 0.03 mm (small) in diameter |

Closing force | 11.5 kN |

Torque range | Mooney value 0 ~ 200 |

Torque resolution | Mooney value 0.1 |

Controller | Windows-based PC software |

Test modes | Mooney Viscosity Mooney Stress Relaxation Mooney Scorch |

Test output contents | Date, Time, Temperature, Mooney viscosity curve, stress relaxation curve, Mooney scorch curve. |

Air source | Min. 0.5Mpa |

Power supply | 1-phase, AC 220V 50Hz or AC 110V 60Hz |

Mooney Viscometer Features

- The entire machine frame is made of high-strength steel, and the hardness and wear resistance of the die cavity and rotor meet relevant standards.

- Supports manual two-button control for die closure or one-click control via software interface.

- The machine comes with a display screen to display real-time temperature, mold closing status, and rotor status.

- Supports Mooney viscosity test, stress relaxation test, and Mooney scorch test.

- It is equipped with a rapid heating device, platinum resistance, and measurement and control module for heating and precise temperature control.

- It can automatically track changes in the power grid and ambient temperature, and automatically correct PID parameters.

- Rotor torque is collected and presented in real time.

- Used with testing software based on Windows operating system.

- Various test curves can be output, and cursors can be used to read data at any point on the curve.

- Supports switching different units for curve parameters.

- Test results in EXCEL, WORD, and PDF formats can be output and printed.

- Users can automatically complete tests, print and archive without operating a computer.

- The upper and lower dies are easy to disassemble and easy to clean and maintain.

- At the end of the test, the upper and lower dies are automatically opened and the rotor is automatically ejected, which is very convenient to take out the rotor.

- Temperature and Mooney values can be calibrated on the computer.

FAQs About Mooney Viscometer

The Mooney viscosity method uses a Mooney Viscometer to measure the plasticity of rubber compounds. The testing principle is to measure the shear resistance produced by the sample to the rotation of the rotor under a certain temperature, time and pressure, and use the difference in torque to express the plasticity of the rubber material.

The test process is to first heat the die cavity to the test temperature, then put the sample into the cavity and preheat it for a certain period of time. The rotor starts to rotate, and the torque value is continuously collected and displayed on the display. The displayed value is the Mooney viscosity value of the rubber compound. The greater the Mooney viscosity, the higher the viscosity of the rubber material (The smaller the Mooney viscosity, the lower the plasticity of the rubber material). Mooney viscosity values vary due to different test conditions, so the test report must indicate the test conditions. Usually , Mooney viscosity is expressed as ML1+4 100℃. Among them, M means Mooney, L1+4, which means the torque value measured when the large rotor (diameter is 38.1mm) is preheated at 100℃ for 1 minute and rotated for 4 minutes. The measurement range of Mooney viscosity is 0 to 200.

Mooney viscosity reflects the viscosity of the rubber material under specific conditions and can be directly used as an indicator to measure the rheological properties of the rubber material. However, since the measurement speed of this method is slow and the shear rate is small, it can only reflect the rheological properties of the rubber material at low shear rate. If the test speed is increased, the results will be closer to the rheology in actual processing.

The most valuable property of raw rubber is high elasticity, but this property also brings some obstacles to subsequent processing. People need to mechanically process the raw rubber, heat treat it or add certain chemical additives to change it from an elastic state to a soft and easy-to-process plastic state. This is beneficial to the uniform mixing and dispersion of the ingredients, improves fluidity, facilitates molding, and makes it easier to control processing speed and quality. However, the plasticity of raw rubber is not higher, the better. Excessive plasticity will reduce the physical and mechanical properties of the material. Therefore, in the process of masticating raw rubber, we need a way to grasp whether the current degree of plasticity is within the range we want. Mooney viscometer was born specifically to solve this problem. Under certain conditions of temperature, time and pressure, the sample is subjected to continuous torsion in the die cavity. It can produce quantitative values as key indicators for evaluating rubber physical properties and processing performance, and can ensure the quality and stability of rubber products.

The vulcanization index (also called Mooney vulcanization speed) is often used as an indicator of the vulcanization rate of the rubber compound. A small value indicates a fast vulcanization speed; a large value indicates a slow vulcanization speed. It can be calculated using the following either formula:

When using the big rotor:

t35 – t5 =△30t

t35 – the time from the start of the test to the point where the viscosity of the compound drops to its lowest point and then rises by 35 values of Mooney viscosity.

t5 – the time from the start of the test to the point where the viscosity of the compound drops to its lowest point and then rises by 5 values of Mooney viscosity.

When using the small rotor:

t18 - t3 = △15t

t18 – the time from the start of the test to the point where the viscosity of the compound drops to its lowest point and then rises by 18 values of Mooney viscosity.

t3 – the time from the start of the test to the point where the viscosity of the compound drops to its lowest point and then rises by 3 values of Mooney viscosity.

The optimum cure time can be approximately calculated using the following formula:

Optimum cure time (large rotor) = t5 + 10 (t35 – t5)= t5 + 10 △30 t

Optimum cure time (small rotor) = t3 +10 (t18 – t3)= t3 + 10 △15 t

Stress relaxation means that after the material is fixedly deformed, the stress will gradually decrease over time. Stress relaxation is an important property of materials.

Mooney viscosity only reflects the fluidity of rubber after heating, but the speed at which it returns to its original state after the external force disappears cannot be known. Only through the stress relaxation curve can the size of the processed material be more accurately controlled. The Mooney stress relaxation test is that after the viscosity test is completed, the motor brakes within 0.1 seconds, and the twisted rubber in the die cavity will gradually relax. The torque changes are continuously measured to obtain the stress relaxation curve.

When doing the Mooney scorch test, a large rotor with a diameter of (38.10 ± 0.03) mm is generally used. When the sample is a high-viscosity rubber material, a small rotor with a diameter of (30.48 ± 0.03) mm is allowed. The Mooney scorch test temperature is generally 120±1°C. Its purpose is to simulate the temperature of the rubber material during processing and measure the early vulcanization characteristics of the rubber material at this processing temperature. If there are special needs, other tests can be used Experimental temperature.

Sample preparation

1) The sample is two pieces of circular discs, 45~55mm diameter, 6 ~ 8 mm thick, one of which has a ¢8~10 mm hole punched in the middle.

2) The test surface should be free of impurities and pores.

3) After processing, the sample should be stored at room temperature for 2 hours, but should not exceed 10 days.

Operating steps

1) Power on and turn on the machine and computer respectively, and check whether the required tools and accessories are in place.

2) Open the computer testing software and set relevant parameters, such as test temperature, formula selection, test time (preheating for one minute, testing for 4 minutes), etc.

3) preheat the die cavity and rotor to the test temperature and allowing it to reach a stable state. When the Mooney viscometer rotates without load on the rotor, the Mooney value reading on the PC should be within the range of ± 0.5.

4) Open the die cavity, pass the rotor shaft through the center hole of the holed sample, then insert the shaft into the bore of the lower die, finally accurately place the other sample on the rotor. (When testing low-viscosity rubber, you can place a high-temperature resistant film between the sample and the upper and lower dies to prevent the rubber from contaminating the die cavity.) Then quickly close the die cavity, and the system automatically starts timing from the moment the die cavity is closed. The general preheating time for the sample is 1 minute, but other preheating times can also be used as needed.

5) After the sample reaches the preheating time, the system automatically starts the motor to rotate the rotor at a speed of (2.00 ± 0.02) r/m, and immediately automatically records the Mooney values during the test.

6) After 60 minutes of testing, the test can be stopped when the sample still does not appear scorched or its Mooney value does not rise from the minimum value to 18 or 35 Mooney values.

7) After the test is completed, the system will open the die cavity automatically. You can take out the sample, and store or print the testing data.

Result expression

Mooney scorch time is t3 or t5 on the curve.

t3 – the time from the start of the test to the point where the viscosity of the compound drops to its lowest point and then rises by 3 values of Mooney viscosity in the case of a test with a small rotor.

t5 – the time from the start of the test to the point where the viscosity of the compound drops to its lowest point and then rises by 5 values of Mooney viscosity in the case of a test with a big rotor.

Get a Customized Quote for a Mooney viscometer that Best Meets Your Needs

Tell us about your unique testing requirements to get a personalized solution from AmadeTech

Related Posts