Benchtop Two Roll Open Mill

Model

AT-R7024C-76

Applications

Used to plasticize and mix various resins, silicones and additives in small batches for prototyping and sheet forming.

Standards

ISO 2393, ASTM D3182, etc.

Benchtop Two Roll Open Mill Description

Benchtop Two Roll Open Mill is a compact polymer mixing machine used in the laboratory to kead, mix and plasticize various mixtures composed of low-viscosity resins, thermoplastic elastomers, silica gel, pigments, masterbatch, fillers, heat stabilizers, and other additives to obtain a sheet-like material in which each component is evenly dispersed. The resulting material can further be used for color matching comparisons, physical tests, chemical tests, formula development, etc. Please note this tabletop open mill is not suitable for processing rubber materials.

Compared with AmadeTech’s floor-standing laboratory open mills, this benchtop mixing mill has a smaller size and takes up less space, allowing you to put it on a table for material processing. The equipment mainly consists of machine base, frame, front and rear rolls, distance adjustment device, driving device, transmission device, heating device and emergency stopping devices.

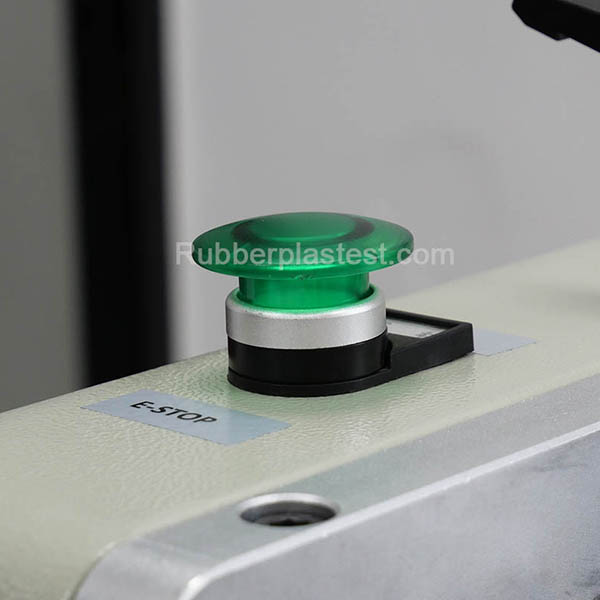

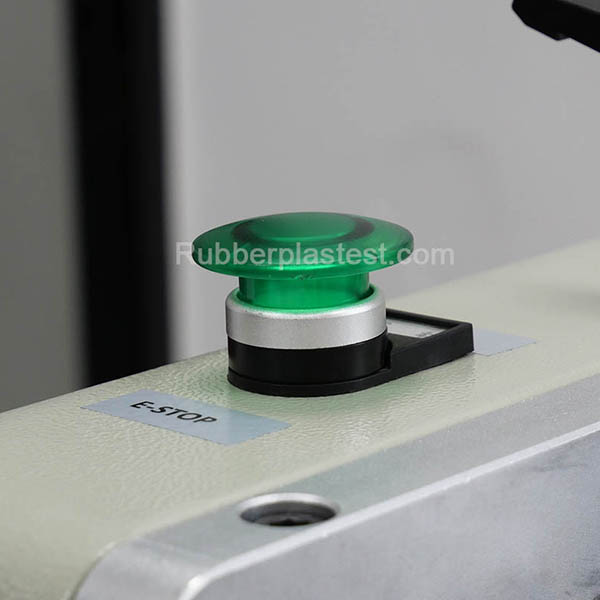

The front and rear rolls are made of high-strength and rigid carbon steel, and the surfaces are chrome-plated to achieve exceptional flatness and finish. The two rolls with the same diameter and length are arranged parallel to the horizontal direction and mounted on both sides of the frame top. They are driven by a reduction motor and the power is transmitted through chains, sprockets, and gear pairs. When you start the machine, the rolls revolve inward relative to each other at different speeds to achieve rolling and mixing of materials in the roll nip. The speed ratio of the front and rear rolls is fixed but you are allowed to freely adjust the roll speed by means of the frequency converter. The cross beam is fixed to the frame by bolts, forming a closed system of forces, which can withstand all loads during work. The Benchtop mixing mill is equipped with two distance-adjusting handwheels and two roll spacing value display indicators. You can turn the two handwheels to adjust the distance between the two rolls and keep them parallel. We configure each machine with a pair of baffle plates on both ends of the two rolls to prevent materials from entering the roll bearings. In order to meet the high temperature requirements when mixing materials, we install electric heating tubes in the inner cavity of each roll. When you enter a desired temperature on the control panel, the roll surface will quickly heat up and maintain the set temperature. The real-time temperatures of the two rolls can be displayed on the digital screens on the control panel. For the sake of safety, we equip the top of each benchtop two roll mixing mill with two emergency stop switches. When an emergency occurs, you can press either switch to quickly stop the machine to protect the operator and the equipment.

Benchtop Two Roll Open Mill Video

Benchtop Two Roll Open Mill - Technical Specifications

| Model | AT-R7024C-76 |

| Roll dia. | 76 mm |

| Roll length | 260 mm |

| Roll hardness | 50 ~ 60 HRC |

| Roll temperature | Room temp. ~ 260 °C |

| Heating mode | Electrical heating |

| Cooling mode | Unavailable |

| Friction ratio | 1:1.27 |

| Roll revolution | Adjustable |

| Roll gap | 0.1 ~ 3 mm adjustable |

| Control mode | Microprocessor |

| Power supply | Single-phase, AC 220 V, 50 Hz or AC 110 V, 60 Hz |

| Dimensions | 800 mm (W) x 400 mm (D) x 600 mm (H) |

Plastic Plasticization & Mixing Principle

When the open mill is working, the two heated rolls rotate inward toward each other at different speeds. The materials stacked above the rolls are entrained into the roll gap due to the friction and adhesion on the roll surfaces, as well as the bonding force between the materials. The materials are subjected to strong shearing and squeezing in the roll gap to cause deformation, thereby increasing the contact interface between the components and producing distributed mixing. When the stress on the materials is greater than the stress they can withstand, the materials will be dispersed. After passing through the roll gap, the material layer becomes thinner and wrapped on the roll of higher temperature. This process is repeated until the desired plasticization and uniform mixing state are achieved.

Benchtop Two Roll Open Mill Features

- The desktop mill’s small size saves laboratory space.

- Easily Used for plasticizing or mixing various resins, silica gels and additives in the laboratory.

- Only a little material needs to be fed during work to save costs.

- The two rolls have electric heating function and the temperature is uniform and stable.

- The heating tubes are easy to replace.

- The roll distance can be adjusted by manual freely.

- The roll speed is adjustable.

- The front and rear roll speed ratio is fixed.

- The whole machine is cost-effective.

- Easy to operate and maintain.

- The mill requires a low power and working voltage can accept AC 220 V or AC 110 V.

Get a customized offer of Benchtop Two Roll Open Mill that Best Fits the Needs

Tell us about your unique testing requirements to get a personalized solution from AmadeTech

Related Posts